Education: Digital X-ray

Over the last few years, as manufacturers and researchers

around the world have taken digital x-ray detectors out of the lab and into clinical

trials, it's become clear that digital x-ray imaging will indeed revolutionize diagnostic

radiology.

In fact, many observers have hailed it as the most significant breakthrough in x-ray

imaging in the last 25 years, referring to it as "the New Modality."

No matter how large or small your facility may be,

it's time to start giving serious consideration to how digital detection will impact

your department and which technology will meet your needs most thoroughly and cost-efficiently.

This tutorial introduces the key concepts around Digital

X-ray technology and analyzes its impact and potential benefits.

Part 1: Overview

From four Components to one

The promise of Digital X-ray

Improving diagnostic confidence

Bottom-line benefits

Part 2: the different Digital X-ray technologies

The GE approach

Alternative approaches to digital x-ray

Part 3: Current Applications

Full Field Digital Mammography

Digital Radiography

All-Digital Cardiology

To understand the potential significance of digital

detectors, consider what happens to the x-rays collected by even a state-of-the-art

conventional x-ray device, such as a radiography & fluoroscopy system equipped

with a digital box: The x-ray signal is transmitted from the tube, through the patient,

and into an image intensifier. Next, the signal is processed through image-intensifier

and camera optics before being sent on to a video camera and through digitization

(Fig. 1a). Finally, the remaining signal is sent on for display and hard-copy generation.

Note that at each stage in this process, the x-ray

signal is degraded to some extent, even if the individual components are optimized

for the application. As a result, typically less than 40% of the original image

information is available for use in image production.

Now consider what happens when we add a digital detector

to the equation: It replaces everything but the x-ray tube and patient (Fig. 1b)!

Because of its high Detective Quantum Efficiency (DQE), it has the potential to

capture over 80% of the original image information. And it equips the user with

a wide range of post-processing tools to further improve that signal ' including

many that can be applied automatically.

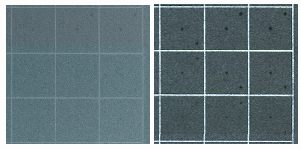

Fig. 1a:

Fig. 1a:

In a conventional, digitized R&F imaging chain, the signal degradation that

occurs with each component consumes more than 60% of the original x-ray signal.

Fig. 1b:

Fig. 1b:

A digital detector replaces all these components, allowing the user to preserve

more than 80% of the original signal ' and to further enhance that signal automatically

or explicitly.

What's more, these advantages are applicable to the

full range of x-ray imaging modalities, including chest and breast imaging, and

in the future fluoro-based applications.

The result? Far more accurate and detailed renderings

of the anatomy of interest ' and a wealth of opportunity for further enhancing the

diagnostic utility of each and every exam you conduct.

The advent of digital x-ray technology means that

the world's Radiology departments will soon participate in a transformation of revolutionary

proportions, and realize revolutionary advantages. Imagine the benefits of routinely:

- Processing image data to highlight regions of interest

and suppress irrelevant information, thereby improving the diagnostic utility of

virtually any study

- Combining image data with other pertinent patient information

available from RIS/HIS systems

- Quickly transmitting the resulting files anywhere over

the networking connections of your choice, including conventional phone lines

- Archiving all this information in minimal space, and

retrieving perfect originals at the touch of a few keys

As already reported by some sites, it won't be much

longer before capabilities such as these become available to all Radiology departments

around the world.

|

Click on image to enlarge

Fig. 2: Magnified Contrast Detail Phantom Images

Left: Images acquired on Film

Right: Images acquired with a Digital detector allow detection of lower contrast

objects than conventional film images

|

Some of digital-detector technology's most obvious potential

advantages fall into the clinical realm.

For example, digital imaging is already proving its

ability to enhance both radiographic and fluoroscopic image quality by improving

latitude, DQE and contrast resolution (Fig. 2).

It's permitting further improvements in the diagnostic

utility of virtually any study through advanced image post-processing techniques.

And it has the potential for lowering patient radiation

dose, not only during the initial exam, but also by minimizing the need for retakes.

The result: improved diagnostic confidence for a full

range of applications.

|

Fig. 3: Potential Impact on Department costs

Over time, departments using Digital-detector technology stand to realize substantial

financial rewards.

|

We can now predict with certainty the financial ramifications

of the Digital X-ray technology. It already seems clear that users will reap substantial

bottom-line rewards as digital technology takes hold, for reasons such as these

(Fig. 3):

- Operating costs should decrease because of dwindling

requirements for film, processing equipment, chemicals, and archiving space ' not

to mention the labor now required for managing these activities.

- Thanks to the inherent speed of digital exams, increased

patient throughput should drive up revenues for facilities with adequate patient

volume ' or, alternatively, allow reductions in the number of rooms and their associated

costs.

- Properly engineered digital detectors may pave the way

for a broad range of future advanced applications, such as Computer Aided Detection

and teleradiology, to permit cost-cutting consolidation of resources.

|